| Topic: Technical discussion | |

|---|---|

|

Edited by

Quietman_2009

on

Tue 02/09/10 12:14 PM

|

|

|

there isn't really a forum for this subject so ya'll move it where you will

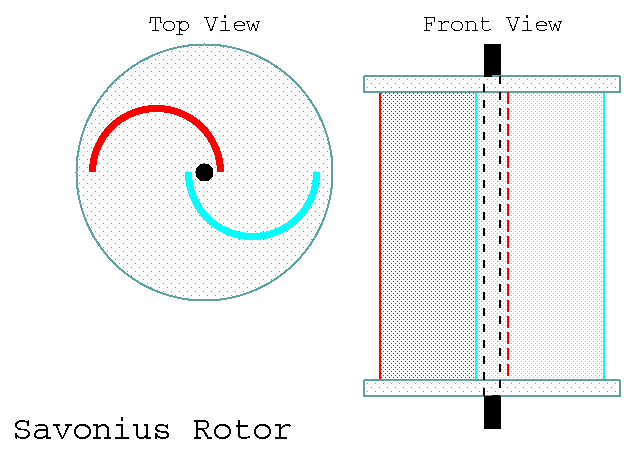

I'm researching and planning to build a wind turbine and would like to hear any input or discussion first, my friends work for a pole line building company so I can get old telephone poles mounted for free. so my thinking is to use a bank of four to six telephone poles with a walkway mounted about halfway up instead of the usual mast. I'm looking at vertical axis turbines versus horizontal a vertical axis turbine has a bit less efficiency than a horizontal but is not as mechanically complex there are a couple of types of vertical axis turbines, the savonius type

the darrius type (this is really difficult to fabricate and has a lot of stress at the middle of the blade)

helical type (this is the one I'm leaning towards but I dont know how hard it will be to fabricate) I have the electronics ability to design and build the rectifiers and limiter circuits so thats not an issue. I'm just wondering if anyone has knowledge or experience with this stuff. No need in reinventing the wheel if someone has already messed with this stuff prolly this thread will just die with no response but its worth a try eh? |

|

|

|

|

|

Edited by

Quietman_2009

on

Tue 02/09/10 12:17 PM

|

|

|

batteries are expensive and a pain in the butt to maintain so my thinking is to use the grid itself as a battery

feed the generated power into the grid (state law requires the power company to pay you the going rate for generated power) and just pull my house power from the grid and use the generated power to offset the charges for my useage. My winter time electricity bill is about $200 a month. If I could offset that it would be definitley cost efficient |

|

|

|

|

|

Quiet I'm not sure if I will be of any help or not but for a do it yourselfer I think the Savonius typpe would be a little easier.Depending on what size you intend to make it I would start with a trailer axlefooor a boat .Depending on your resources in Texasthat will give you a bearing surface ready made for a sealed bearing .Then obviously you would need a pipe with the right diameter to seat the outside surface of the bearing .Weld one end of axle to a riser pipe comeing from the ground .You may need the assistance of a machine shop to get it balanced though,as I would think that to be important.Thats about the easiest thing I could think of !

|

|

|

|

|

|

I wish I had the electrical knowledge for the rest I'd build one myself !My knowledge ends at wireing my house !No technical stuff.

|

|

|

|

|

|

I wish I had the electrical knowledge for the rest I'd build one myself !My knowledge ends at wireing my house !No technical stuff. Thats about where my knowledge ends too, sorry Quiet. Let me say I am impressed and hope you achieve what you are setting out to acomplish. I think the first diagram would be the easiest too. I wonder if you could make double spinny things to make it generate more juice. Ya I know I used the word thingy. I may be able to build stuff but I sure can't tell you what stuff is called half the time.

|

|

|

|

|

|

I'm thinking of the savonius type too

imagine a barrel cur in half and the two halves offset but then I figure why stop there and make it stack of four or so high here is a cross section look of a savonius style

and then build four or five of em side by side. That ought to overcome the lack of efficiency in the style |

|

|

|

|

|

I wish I had the electrical knowledge for the rest I'd build one myself !My knowledge ends at wireing my house !No technical stuff. Thats about where my knowledge ends too, sorry Quiet. Let me say I am impressed and hope you achieve what you are setting out to acomplish. I think the first diagram would be the easiest too. I wonder if you could make double spinny things to make it generate more juice. Ya I know I used the word thingy. I may be able to build stuff but I sure can't tell you what stuff is called half the time.

hahaha I say thingy and doodad thingamajig and chingalera (oops, thats a bad word. it means "little effing thing") |

|

|

|

|

|

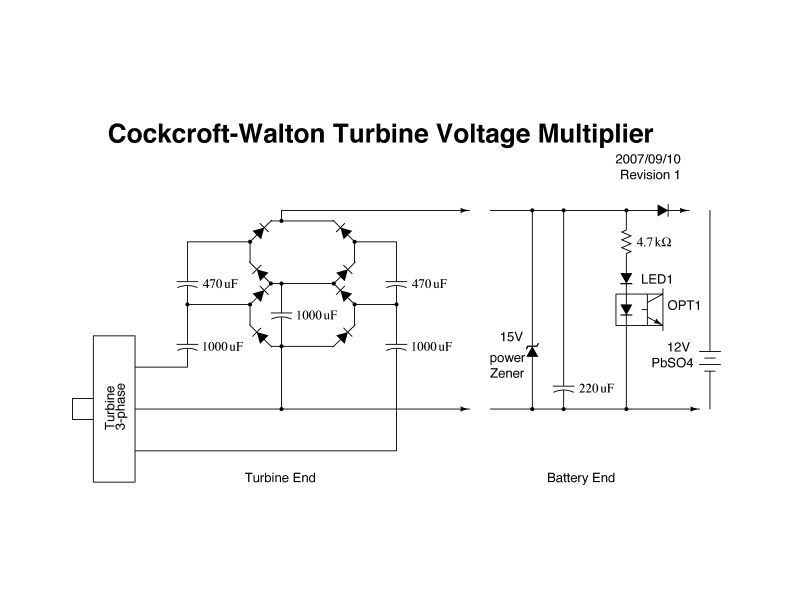

using the vertical shaft from the turbine will make it easier to build the windings for the generation of power

I plan to make my own windings (I could use a low RPM DC motor which will generate electricty when mechanically operated but they cost money and winding my own will be more fun) everything is based on the idea that if you move a conductor (wire) through a magnetic field it will produce electricty I have found a few sources for rare earth magnets that arent too expensive. so if I wind some coils and have the magnets cut those coils with the turbine revolution I can generate 12 volt I'll have to put in a limiter circuit for when the turbine is hauling azz and a bridge rectifier to keep it clean |

|

|

|

|

|

Edited by

Quietman_2009

on

Tue 02/09/10 12:59 PM

|

|

|

something along the lines of this

the rectifier will keep it clean (and one way) and the zener will limit it to 15 volts so I dont blow the batteries (if I use em) but I dont know about using three phase. that seems unecessary and a pain in the azz. But then the disribution lines are three phase |

|

|

|

|

|

I have to run for a haircut appointment

I'll check back here later and see if anyone has anything to add all comments are welcome. even non technical, smart alecky or off topic kibbutzing haha. it dont bother me |

|

|

|

|

|

Quiet I'm not sure if I will be of any help or not but for a do it yourselfer I think the Savonius typpe would be a little easier.Depending on what size you intend to make it I would start with a trailer axlefooor a boat .Depending on your resources in Texasthat will give you a bearing surface ready made for a sealed bearing .Then obviously you would need a pipe with the right diameter to seat the outside surface of the bearing .Weld one end of axle to a riser pipe comeing from the ground .You may need the assistance of a machine shop to get it balanced though,as I would think that to be important.Thats about the easiest thing I could think of ! I'm thinking of using bicycle wheels for the bearings. cut out the spokes and bolt a flywheel on it. they are cheap and and are relatively frictionless. And the central shaft could be say 2" PVC or so |

|

|

|

|

|

Not sure of the load on those bearings plus they're not sealed.You would have maintenance there.Could use the top and bottoms of the barrell to be your top and base for the vanes too.

|

|

|

|

|

|

Dude! Log onto popsci.com

Should be an issue 3-4 months back that has an awesome design for plug and play vert. Wind turbines that go for $380. Super efficient. The whitehouse is installing them and the production ratio is unmatched. I give away all my old issues so I can't nail it down for you but I think they are called jellyfish turbines. |

|

|

|

|

|

Edited by

Quietman_2009

on

Tue 02/09/10 07:01 PM

|

|

|

I'll see if I can find that

I did come across jellyfish turbines while I was reading but now I cant remember what was diff about em I talked to my friend this evening (he made me watch Wheel of Fortune with him) and he has a pile of discard telephone poles (and access to a hole digger) we're thinking to plant em about six feet apart and put a catwalk of 2x6's about three quarters of the way up and mount an array of 4 or 5 turbines with the shafts running through the catwalk below I'll have to take pictures as we go |

|

|

|

|

|

That sounds cool as I would love to know how it works out .My soninlaw has a cabin in the sticks that would definatelly benifit from one with reasonable costs !

|

|

|

|

|

|

Edited by

Quietman_2009

on

Tue 02/09/10 07:11 PM

|

|

|

That sounds cool as I would love to know how it works out .My soninlaw has a cabin in the sticks that would definatelly benifit from one with reasonable costs ! this site has several designs for horizontal axis machines. this is where I got the designs to wind my own coils http://www.otherpower.com/learningcurve.html |

|

|

|

|

|

Thank you I will put them in my favorites

|

|

|

|

|

|

they make the vanes from PVC pipe. you can cut them from 10 inch PVC and the curve is perfect aerodynamic vanes

|

|

|

|

|

|

Just make sure you install a manual or auto shut down mechanism to hold them stationary when we get the days of +45 winds. If you never seen a wind turbine shred it's self.....it is truly creepy s**t.

|

|

|

|

|

|

they make the vanes from PVC pipe. you can cut them from 10 inch PVC and the curve is perfect aerodynamic vanes |

|

|

|

|